Street Flooding Due to Failing Infiltration Systems – Yakima, Washington (Source: Aspect Consulting)

The Pacific Northwest recognized early on the negative effects of urbanization on receiving waters and has been a leader in the stormwater management field for decades. This was initially driven by concerns about the impacts of urban runoff on threatened and endangered species in the Puget Sound area, and later reinforced by the National Pollutant Discharge Elimination System (NPDES) permitting program.

More recently, a study led by the University of Washington solved the mystery of why Coho salmon are dying in urban streams before spawning. As many suspected, stormwater runoff is the culprit. It was found that runoff from high traffic areas contains a tire-related chemical that is toxic to Coho.

As the science of stormwater management continues to progress, practitioners must learn about and apply the latest techniques, including the use of stormwater infiltration. While infiltration is not really a new concept, widespread infiltration design is new for some areas and some water quality designers. When infiltration systems fail, the consequences can range from increased pollutant loading and erosion in streams to flooded roads, businesses, and homes.

Infiltration Design For Cleaner Water and Better Habitat

Many agencies operate stormwater programs under NPDES Municipal Separate Storm Sewer System Permits (MS4 Permits). MS4 Permits require development projects within the permittee’s jurisdiction to include permanent Best Management Practices (BMPs) to reduce stormwater pollution and flow-related problems. Permanent BMPs typically include detention vaults, filters, and bioretention basins.

Over the last decade, MS4 Permits have started requiring the use of infiltration BMPs to mitigate the hydrologic and water quality impacts of development. From a surface water perspective, infiltrated runoff does not cause stream erosion, has no pollutant loading, and helps recharge groundwater.

Using Infiltration to Reduce Hydrologic and Water Quality Impacts (Source: Aspect Consulting)

Lessons Learned from the Track Record of Filtration and Infiltration

Much like the early application of other stormwater BMPs, some designers don’t have a technical background in infiltration. Numerical models, simplifying assumptions, and step-by-step procedures make applying infiltration feasible for generalists, but there are some key issues to consider.

Accurately Estimating Infiltration Rates. The starting point for designing an infiltration BMP is determining the infiltration rate your BMP is expected to have. Allowable methods have changed over the years, with some agencies requiring in-situ infiltration testing for all infiltration BMPs, and some allowing “grain size methods” to estimate rates in certain cases. It’s recommended to only use grain size methods for screening purposes when soils meet all criteria for application of the equation being used.

Reliance on grain size method results can backfire, which is why in-situ infiltration testing must be done to support the design process, with knowledgeable analysis of testing results. The number of infiltration tests should scale with the size, complexity, and soil heterogeneity of the project site. Thoughtful testing and analysis methods can also indicate if groundwater was mounding during the test, and whether a formal mounding analysis is needed.

Once correction (safety) factors are applied, there are generally two ways an infiltration rate is used to help model and design infiltration BMPs: (a) assume the infiltration rate is constant during BMP filling and emptying; or (b) assume the infiltration rate varies (typically linearly) with water depth (pressure head) above the infiltration surface. Knowing how the infiltration BMP will be sized is important when analyzing test data because the resulting constant infiltration rate will not necessarily be the same value as the variable rate.

Extreme plugging/sediment loading to a proprietary stormwater filter (Source: Oregon Department of Transportation, Operation and Maintenance Manual, DFI No.: D00183, 2011)

Plan to Manage Plugging. Infiltration BMPs are susceptible to the same plugging by stormwater sediments and biofouling that stormwater filters are. Stormwater filters plug up and infiltrating into soil is like infiltrating into a filter. Therefore, pre-treatment to remove sediment is necessary to prolong the life of infiltration BMPs.

Plugging of the infiltration surface is the main reason safety factors are used when sizing infiltration BMPs. Stormwater manuals often prescribe safety factors, but the safety factor really should scale based on the soil being infiltrated into.

For instance, when infiltrating slowly into a fine soil with a permeability not much higher than stormwater sediment, reducing the measured rate by a factor of 2-4 is acceptable. But when infiltrating into coarser soil with a permeability much greater than stormwater sediment, a larger safety factor is warranted (some jurisdictions do set a maximum design infiltration rate). The level of treatment for sediment removal prior to infiltration should affect the safety factor too.

Check and Address Groundwater Mounding. Infiltrating runoff sometimes causes groundwater mounding. As mounding increases, it can reduce the infiltration rate, cause seepage problems, and raise regulatory compliance concerns. We recommend monitoring groundwater during infiltration testing to see if it rises in response to the test. If so, the data can be used to help calibrate a mounding model. In cases where mounding is an issue, a formal analysis and modeling (such as USGS’s MODFLOW) of the receptor soil/aquifer combination should be done and infiltration BMP flowrates and spacing fine-tuned to avoid mounding problems.

Increasing Focus on Deep Infiltration to Meet Low Impact Development Goals

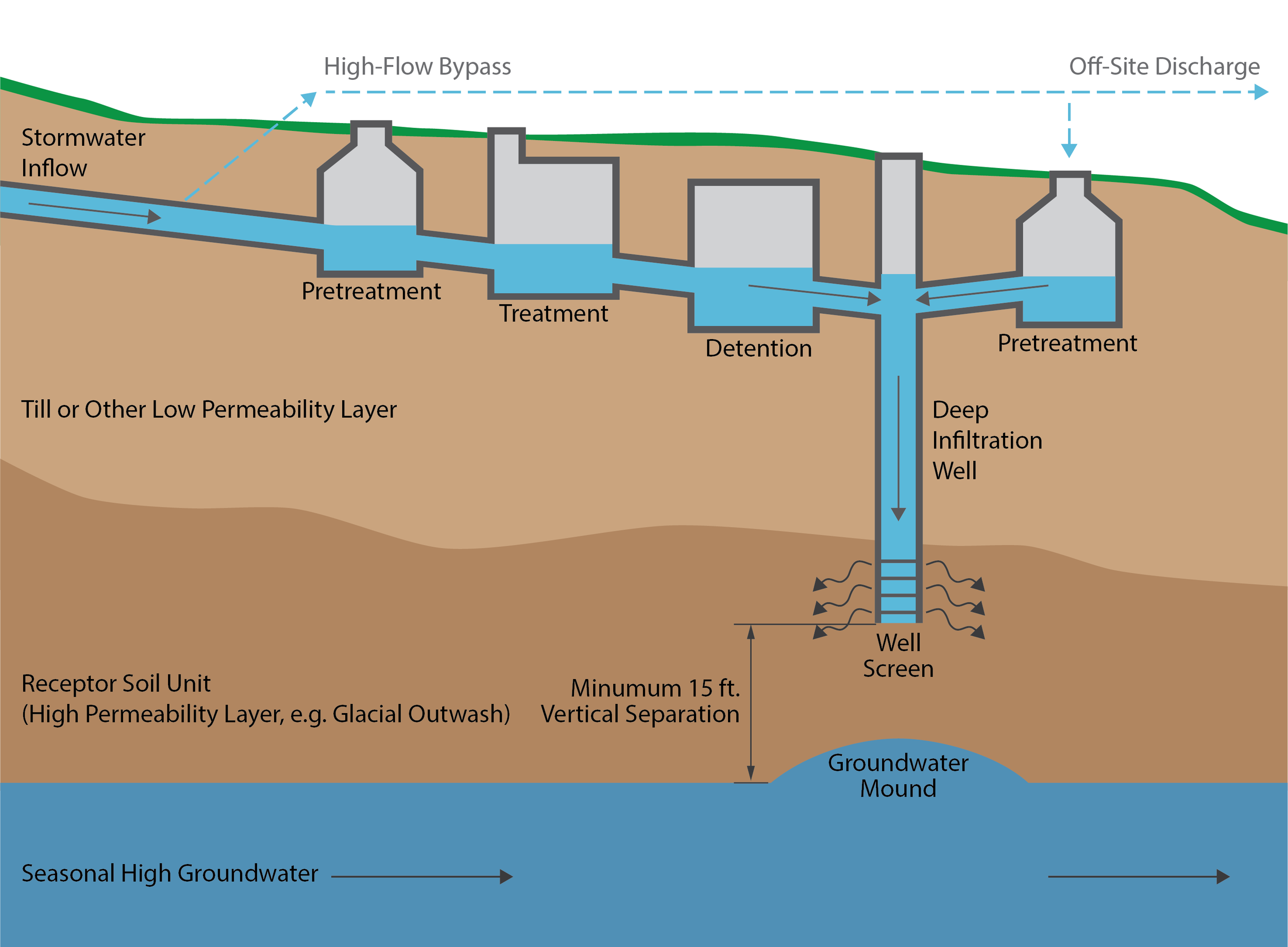

The use of “deep” infiltration to meet project Low Impact Development and flow control requirements has been increasing, particularly where surface soils have low permeability but overlie an unsaturated higher permeability soil. It can be feasible to bore through the surface soil and install an infiltration well in a more permeable receptor soil. Stormwater runoff is routed into the well and infiltrated into the receptor soil.

Simplified Deep Infiltration Schematic (Source: Aspect Consulting)

The concept of deep infiltration is straight forward but a system that reliably functions for decades requires some careful thought. To prevent plugging, it’s critical to keep sediment out of deep infiltration wells. However, normally some runoff is allowed to bypass treatment BMPs during large storms. Directing untreated flow into infiltration wells will reduce their service life. Another consideration is whether advance BMPs can be a source of initial sediment loading including: Is that drain rock really clean? Should I specify on-site washing of drain rock? Will my bioretention mix initially leach sediment? Should I flush the system before connecting to infiltration BMPs?

We recommend designing deep infiltration wells to:

Include treatment to remove sediment for

all flows to the wellControl the rate of flow into the well to

the design rateReserve head to allow water levels to rise to counteract plugging

Prevent baseflows from entering infiltration wells

Ensure the system drains down in a

reasonable time

Using the ‘Infiltration Cookbook’: Infiltration System SOPs

Consistent and successful stormwater infiltration requires clear and comprehensive guidance for planning through construction. As part of the team preparing an updated LID Manual for the Port of Seattle’s Seattle-Tacoma International Airport (STIA), Aspect developed Standard Operating Procedures (SOPs) for shallow and deep infiltration systems. The detailed SOPs for the Port of Seattle— both for shallow and deep infiltration — are publicly available and are a good example of a successful ‘cookbook’ for creating sustainable infiltration design.

SOPs provide guidance for planning, testing, analysis, design, and construction of infiltration facilities. Recommended SOP steps for deep infiltration are shown here:

For more information about soil infiltration best practices for water quality and stormwater issues, contact John Knutson.

An edited version of this article appeared in the February 2022 version of Stormwater Magazine.