Environmental Technical Exchange

Figure Credit: US Environmental Protection Agency

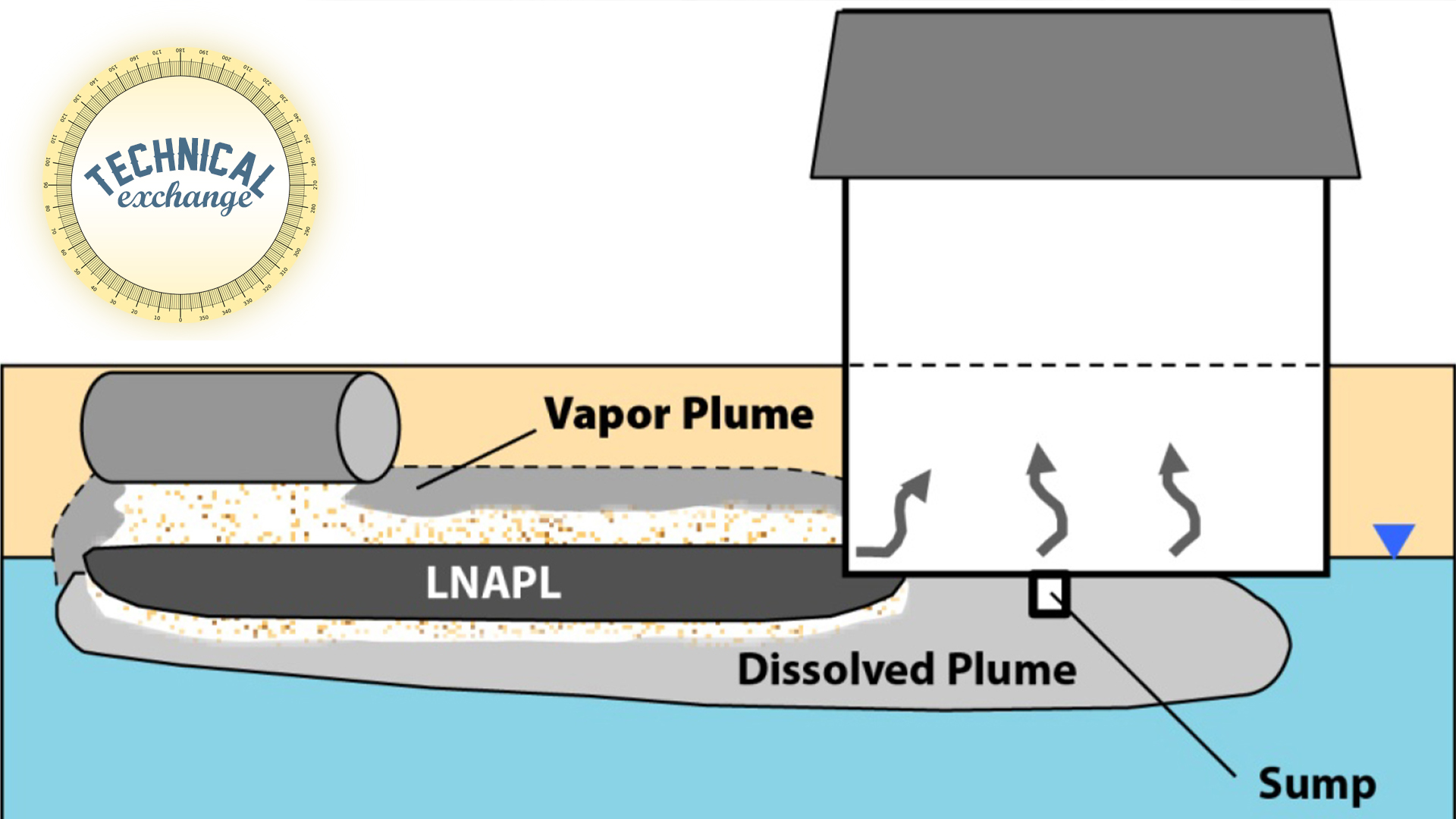

When volatile chemicals have the potential to migrate from contaminated groundwater or soil into an overlying building—i.e., vapor intrusion (VI)—a whole new layer of complexity is added to environmental remediation projects. In Washington State over the last several years, vapor intrusion has been under increasing regulatory scrutiny. An understanding of vapor intrusion typically revolves around a few core questions:

- How to accurately evaluate it?

- How to keep abreast of what’s required, given that the regulatory guidance is constantly evolving?

- How to protect human health during and after site cleanup?

During Aspect’s monthly technical exchange series, Eric Marhofer, Dave Heffner, Carla Brock, Eric Geissinger, and Kirsi Longley of our environmental team gave a roundtable presentation of their collective experience at assessing vapor intrusion at well over 100 sites.

Everyone has to Breathe

As one of our engineers pointed out, you can avoid drinking contaminated water or eating from contaminated soil, but everyone has to breathe. Thus, suspect air quality and what to do about it is a sensitive topic. Protecting the health and safety of occupants in buildings above or near subsurface contamination is priority number one. Property owners also want to protect their investment from future liability and steer clear of potential regulatory roadblocks to developing or selling a property.

When Do We Worry About Vapor Intrusion?

In general, vapor intrusion is a concern if soil or groundwater contaminated with volatile organic compounds (VOCs) exists within 100 feet of occupied structures. The typical culprits are:

- Petroleum hydrocarbons (e.g., from gas stations and other sites with leaking underground fuel storage tanks and pipelines); and

- Chlorinated hydrocarbons such as trichloroethene (TCE), tetrachloroethene (aka perchloroethene or PCE), and vinyl chloride (e.g., from dry cleaning, vapor degreasing, and circuit board manufacturing sites).

Effective VI Assessment

As explained by the presenters, assessing vapor intrusion risk requires distinguishing between ambient air quality (i.e., the air we breathe in a given space) versus impacts to air from a potential subsurface contamination source. Doing this can get complicated, since residences and other occupied structures typically contain common chemicals—household solvents, gasoline, and cleaners, for example—that can contribute to degradation of indoor air quality. Managing the concerns of anxious tenants, occupants, and property owners can further complicate the assessment process.

Many lines of evidence are required to effectively evaluate vapor intrusion. Successfully characterizing the VI pathway and risk level at a site may require sampling some combination of groundwater, soil, soil gas, outdoor air, and indoor air, as well as predictive modeling when appropriate. And a well-designed sampling plan must be matched with a good understanding of relevant regulations and regulatory guidance, which are constantly evolving. VI assessment must consider guidance from a wide range of applicable resources, including the Washington State Department of Ecology (Ecology), U.S. Environmental Protection Agency (EPA), Interstate Technology Regulatory Council (ITRC), and American Society for Testing and Materials (ASTM).

What's New in Vapor Intrusion Regulations and Guidance

The presenters highlighted several VI-related regulatory changes that have occurred over the last few years:

Short-term TCE exposure. The EPA issued new guidance on TCE in late 2012 regarding short-term exposure limits for pregnant or potentially pregnant women. Recent studies suggest that short-term exposure to TCE above 2 micrograms per cubic meter (ug/m3) in any 3-week period during the first trimester of pregnancy poses a risk for heart defects in developing fetuses. This has implications for sites where TCE is a potential VI concern because it could mean extensive/expensive monitoring in buildings where women of child-bearing age live or work.

Screening for petroleum hydrocarbon sites. Recent guidance released by the EPA and ITRC provides updated screening distances for assessing vapor intrusion at sites potentially impacted by petroleum hydrocarbons. The new guidance recognizes that bioattenuation is a factor for petroleum hydrocarbon releases, and allows for screening distances shorter than 100 feet (the default distance) that can be used to preclude further assessment. This may provide an early “off-ramp” for petroleum hydrocarbon sites where sampling may have previously been required.

New naphthalene screening and cleanup levels based on cancer effects. Recent guidance from Ecology considers naphthalene a carcinogen and sets new screening and cleanup levels for groundwater and air that relate to evaluation of the VI pathway. The new screening level for naphthalene in groundwater for consideration of the VI pathway is 8.9 micrograms per liter (ug/L), and the cleanup level for indoor air is now 0.074 ug/m3 (previously 160 ug/L and 1.4 ug/m3, respectively). This may be an important consideration for sites where naphthalene was previously not considered a chemical of concern.

“New” ASTM Phase I Standard. The most recent ASTM standard for Phase I Environmental Site Assessments, a common due diligence step for property transactions, now recognizes vapor as an environmental concern and includes screening for vapor sources as part of the standard. Screening for vapor sources is expected to result in an increase of recognized environmental concerns (RECs) during the Phase I process and more Phase II investigations to define risks and liability for property owners, lenders, and insurance companies. This will be a challenge given the fast pace of property transactions, and the relatively short due-diligence period typically afforded to prospective buyers.

Vapor Intrusion Applications in Action

The presentation closed on a roundtable presentation of practical vapor intrusion applications at a variety of sites.